BREAD 210

1310CORELESS Multi-Layer Steel Blade Stainless Steel Handle

As its name suggests, the blade literally has no core blade but is instead made up of an accumulation of 69 layers using two types of steel, which create unique patterns on the blade’s surface. Due to its layered structure, the blade is stronger and more rigid than those using only a single steel. This completely original design achieved by Japanese artisan is the only blade of its kind in the world.

Clad metal for the highest quality

The material used for the blade is clad metal manufactured using world-leading techniques by local companies in Echizen, which has extensive experience in this field. Clad metal is produced by forging different layers of metal together, taking advantage of the strength of each piece as an integrated unit while ensuring any weaknesses are balanced out by each layer. The steel is composed of a perfect blend that produces a long-lasting, greatly long-sharpness, hard to bend or break, and rust resistant.

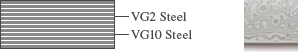

CORELESS is remarkably first successful with VG2 and VG10

CORELESS material is able to complete this unique and difficult our joining clad technique of the fold forging by using the original peculiar to technique. CORELESS made by VG2 and VG10 which manufactured at local material company. Alternating core material repeatedly, it is achieved a steel structure which is finer “unprecedented sharpness”, “unprecedented strength”, and “unprecedented layer pattern”.

| VG2 | Carbon | Chromium | Molybdenum | ||

|---|---|---|---|---|---|

| 0.6% | 14.0% | 0.2% | |||

| VG10 | Carbon | Chromium | Molybdenum | Vanadium | Cobalt |

| 1.0% | 15.0% | 1.0% | 0.2% | 1.5% |

Stainless handle

Stainless handle series is designed by Mr. Chiaki MURATA at the former Japan Brand project. For sturdy handle parts and blast finished. It has a spoon cut configuration parts for the joint between blade and handle with weight and shape. Total design keeps the best balance for fit and comfort of use.